Vol. 39 (Nº36) Year 2018. Page 29

Vol. 39 (Nº36) Year 2018. Page 29

Franz SHEREGI 1; Vladimir SAVINKOV 2; Pavel BAKLANOV 3

Received: 18/05/2018 • Approved: 28/06/2018

ABSTRACT: The urgency of the problem discussed in the article is justified by the acceleration of the rotation of the nomenclature of goods both on the domestic and international markets. This assumes the economy's support for innovative products. The experience of Russia shows that the scientific cooperation of universities and manufacturing companies involves a number of problems that reduce the effectiveness of this interaction. The article is devoted to identifying these problems in order to determine the path of their correction. |

RESUMEN: La urgencia del problema discutido en el artículo se justifica por la aceleración de la rotación de la nomenclatura de mercancías tanto en el mercado nacional como en el internacional. Esto supone el apoyo de la economía para productos innovadores. La experiencia de Rusia muestra que la cooperación científica de las universidades y las empresas manufactureras implica una serie de problemas que reducen la efectividad de esta interacción. El artículo está dedicado a identificar estos problemas para determinar el camino de su corrección. |

An important condition for intensification of development and optimization of the national economy is its optimization through the widespread introduction of information technologies, as forms of unification of goods and communications. Today, the government of Russia is trying to take into account the objective trend of increasing the role of science in production, subsidizing innovative production, designed to promote the rotation of the product range, increase the dynamism and variability of mass consumption.

In economically developed countries, the intensification of the introduction of science into production occurred in the 1970s and 1990s through the association of research results of universities and autonomous research organizations in direct partnership with manufacturing companies (the creation of technological platforms). By the end of the 1990s, there were about 300 technical parks in the world, and in the period from 2000 to 2010, their number increased 2.5 times. However, the synchronous interaction between partners (universities and manufacturing companies) did not work, since the dependence of production on market demand does not allow either to transfer scientific products to the innovative product, either by technology or product, at such high rates as science can develop. As a result, the expected economic effect from the creation of technological platforms in economically developed countries did not happen (IASP, 2018; Heifets and Selekhov, 2010).

As for Russia and developing economies as a whole, they face the task of saturating the market with their own products, which are competitive with respect to the exported goods, which will help reduce imports to an acceptable optimum. In the expansion of the role of the national economy in the domestic and international markets, the state is interested, so in 2010 in Russia, it was decided at the state level within 10 years (2010-2020) to implement budget stimulation of innovative products in the form of interaction between university science and manufacturing enterprises (Žižka et.al., 2018). The objectives of the cooperation of the scientific activity of universities and industrial enterprises in the interests of the development of innovative production, as well as the ratio of budgetary and non-budgetary funding for this cooperation, are determined by the decree of the Government of the Russian Federation N218 of 09.04.2010 (Decree 218, 2010). The priority areas of science, technology (7 in all) are approved by Presidential Decree of 07.2011 N 899 (Decree 899, 2011), within which scientific projects should be aimed at promoting the development of innovative production. Priority directions serve as an indicator of the relevance of applied scientific research, which is a technological platform for scientific cooperation of universities and manufacturing companies: security and counteraction to terrorism; the industry of Nano systems; information and telecommunication systems; life science; rational nature management; transport and space systems; energy efficiency, energy saving, nuclear energy.

Despite the state subsidizing of innovative products in Russia, for ten years the ongoing economic crisis has reduced the effectiveness of innovative cooperation between universities and manufacturing companies. The authors of this article in their research aimed to find out how the interaction between universities and manufacturing companies develop in the development of innovative products in the conditions of the economic crisis, how effective and promising this interaction is. The authors formulate the answer to this question based on the results of more than 20 all-Russian expert surveys conducted in the period 2011-2018.

For the period 2010-2020, Russia gave priority to the development of its own market, placing a stake on the transfer of scientific products of universities to expand innovative production. The prospects of this approach to stimulating economic development, the developers of the state program of interaction between universities and manufacturing companies based on the previous experience of economically developed countries (Casper, 2007). In the 2000s, many countries, which are at the stage of developing economies, turned to this experience making a bet on the development of national innovative production facilities based on technology parks and platforms (Kang, 2014). Mass formation of new types of clusters with high innovative potential began (Bunyak, 2016). In a relatively short time (5-7 years), successful projects were implemented for the production of science-intensive competitive products FONTAR (Argentina) (Castillo et.al., 2014), FNDCT (Brazil), FONTEC (Chile) (Rehman, 2017), COLCIENCIAS (Colombia). But countries that achieved rapid economic growth (for example, South Korea, China, Spain, and Turkey) turned to this experience (Link and Yeong Yang, 2017).

As for the Russian Federation, technical parks have existed for more than 25 years and they have contributed to the development of a number of new technologies that have been successfully operating in production to date (Kotelnikov and Nagaeva, 2014). The expansion of innovative products in the domestic market of the country by many economists and social scientists has been perceived as a sufficient step for Russia's entry into the number of economically highly developed countries, although it is not always possible to unambiguously determine the competitiveness in the international market for goods and services planned for the production of innovative products (Gorshkov and Sheregi, 2011).

It is necessary to reckon with the growing deficit of specialists. The forecast of the change in the population of the Russian Federation until 2035, carried out by the Center for Social Forecasting and marketing, indicates the beginning of a reduction since 2026 of graduates from universities and postgraduate courses, which will lead to a shortage of specialists in high-tech production (Center of Social Forecasting and Marketing, 2017). Already today, the deficit of highly qualified specialists in Russian manufacturing companies participating in technological platforms is on average 35% (Osipov and Sheregi, 2017). Studies conducted by the specialists of the Institute of Sociology of the Russian Academy of Sciences show that in Russia the problem of educational mobility of specialists in the form of continuing education is not yet solved on a qualitative level, which makes their accelerated qualification rotation difficult (Gorshkov and Klyucharev, 2011). In the development of corporate education in Russia, it would be necessary to reach the level available in economically developed countries (Bajada and Trayler, 2013). Including the existing experience of commercialization of knowledge by universities and research organizations through research and development (Etzkowitz, 2018).

Despite the listed problems that arose in the process of stimulating the development of innovative production by the state, in May 2016 the orientation towards such a development of interaction between university science and production was confirmed by the President of Russia in the form of strategic goals, according to which by 2025 the country should be included in the number of five economically most developed world powers (Decrees, 2018). What can the scientific cooperation of universities and industrial enterprises give in this task? Consider the question posed in support of the results of all-Russian expert surveys.

The effectiveness of scientific cooperation between universities, research organizations and manufacturing companies was studied by the authors in 2011-2018 according to a unified methodology in the form of repeated expert interviews. The research was carried out by the Institute of Sociology of the Russian Academy of Sciences, the Institute of Socio-Political Research of the Russian Academy of Sciences, Center for Social Forecasting and Marketing LLC (Savinkov and Baklanov, 2016). A total of 4,550 experts were surveyed at universities, academic and entrepreneurial research organizations, and in manufacturing companies.

As the initial hypothesis of the study, it was suggested that the interaction of universities and manufacturing companies in implementing the state scientific program in the interests of developing national innovation production, based on the organizational, technical, technological and financial potential of the three partners - universities, research organizations and manufacturing companies, close cooperation. However, by 2017, most of the research organizations, primarily academic ones, have withdrawn from the partnership, and today production companies are implementing a state-subsidized scientific project, mainly with universities. The weak interaction of research organizations with manufacturing companies and universities is the result of a systemic crisis in Russian science, which in the last 20 years has led to the loss of some leading scientists (and due to the lack of economic interest among young people in this field of activity, and because of age, migration ), since the end of the 1980s most of the scientific organizations did not carry out commercially significant studies. In addition, most research organizations, due to the lack of necessary finances, could not acquire modern technology, experienced laboratories, testing facilities and test site.

The data of the all-Russian expert survey form the basis for an empirical test of the effectiveness of scientific cooperation between universities and research organizations with manufacturing companies. Selection of interviewers of researchers, heads of creative and project teams took place in production companies, universities and their research units of 46 subjects of the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Belgorod, Bryansk, Vladimir, Volgograd, Voronezh, Zabaikalsky, Ivanovo, Irkutsk, Kaluga, Kemerovo, Kostroma, Kursk regions, Krasnoyarsk Territory, Lipetsk, Moscow, Nizhny Novgorod, Novgorod, Novosibirsk, Orel, Penza, Pskov regions, Perm, Primorsky Territory; Republics: Bashkortostan, Buryatia, Karelia, Crimea, Tatarstan; Rostov, Samara, Saratov, Sverdlovsk regions, Stavropol Territory, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk regions, Khabarovsk region, Chelyabinsk, Yaroslavl regions.

In Russia, one of the first practical steps of the state to provide conditions for the cooperation of universities and manufacturing companies, commercialization of scientific activity of universities, was the granting of the right to establish small innovative enterprises, as autonomous business organizations that facilitate the transfer of scientific products produced by universities. By the end of 2011, 1048 small innovative enterprises were registered in the electronic database of the Ministry of Education and Science of the Russian Federation. However, as the analysis of the dynamics of the number of small innovative enterprises of universities in 10 years of operation showed, in most cases, their economic activity was possible only in reliance on budgetary sources. But since budget sources were often not sufficient even for simple reproduction of economic activity, by 2017 about 40% of small innovative enterprises of universities ceased their activities (Klyucharev et.al., 2017).

Another problem that hampered effective cooperation between universities and manufacturing enterprises in the interests of developing innovative products is the disregard of the detailed development of a business plan containing a forecast of commercial risks at various stages of interaction (Klyucharev and Popov, 2017).

Despite these shortcomings, in Russia from 2010 to 2018 significant results were achieved in the scientific cooperation of universities and manufacturing companies in the interests of developing innovative products. However, as evidenced by the dynamics of comparable indicators, formed as a result of repeated Russian expert surveys conducted by the authors, problems remained that consist in a valid assessment of the sustainability of risks. According to the data in Table 1, the risks identified by experts, which remain valid from the beginning of the scientific interaction of universities and industrial enterprises, form three groups: organizational-financial (lines 1-3), personnel (lines 4-5), and marketing (lines 6-7).

Table 1

The share of experts who pointed to the presence of risk in achieving target

indicators of scientific projects implemented by universities in conjunction with

regional manufacturing enterprises, %

Risks to achieving target indicators |

Year of study |

||

2013 |

2015 |

2017 |

|

1. Objectivity of the deadlines for the implementing a scientific project |

49.0 |

84.6 |

66.7 |

2. Objectivity of the organizational plan for the implementing a scientific project |

34.4 |

76.9 |

50.6 |

3. Conformity of the amount of financing of a scientific project to the value of research costs |

47.9 |

50.0 |

46.9 |

4. Conformity of the qualification composition of researchers to the tasks of the scientific project |

60.4 |

84.6 |

53.1 |

5. Compliance of the technical and technological potential of the research team with the tasks of the scientific project |

52.1 |

53.8 |

59.3 |

6. Guarantee of assistance to the product received as a result of the scientific project to strengthen the company's position in the internal profile market of goods and services |

32.3 |

42.3 |

40.7 |

7. The maximum duration in time of profitable use by the company in the production of a scientific product obtained as a result of the implementation of a joint project |

14.6 |

11.5 |

30.9 |

The data in Table 1 indicate that in Russia the implementation of the first joint scientific projects of universities and manufacturing enterprises has been more burdened by risks than expected. What is the reason for that?

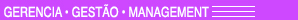

Most universities started scientific cooperation with production organizations in the fall of 2010, after the release of the Government Decision No. 218. (Decree 218, 2010) by mid-2011, organizational mechanisms for scientific cooperation in all priority areas were formed only in 30% of universities that have partnered with industrial enterprises to implement a scientific project. One of the problems hindering the systematic organization of interaction between universities and manufacturing companies on a joint scientific project was the absence in 60% of cases of a well-developed business plan that would serve as a valid “road map”. A comparison of the data for 2011-2017 is also indicative of a significant but not complete improvement in the situation - the availability of a business plan in only 65% of cases (Figure 1).

Figure 1

The availability of a joint business plan for the implementation of the

scientific program for universities and manufacturing companies, %

As evidenced by the data of 4 repeated expert interviews, in most universities and production enterprises that jointly carry out the scientific project, the forecasted technologies for calculating the stable functional indicators of the business plan are still poorly developed. The difficulties are primarily in the exact calculation of the project cost, the planned period for the implementation of the study, a reliable assessment of the market situation and the commercialization of the innovative product (Table 2).

Table 2

The share of experts who pointed to the conceptual difficulties in calculating the

sustainable functional indicators of the business plan for joint implementation

of the scientific project by universities and manufacturing companies, %

Risk factors |

Year of study |

|||

2011 |

2013 |

2015 |

2017 |

|

The expected innovative effect of a scientific product is weakly predictable |

47 |

51 |

54 |

51 |

It is difficult to unequivocally determine the sufficiency of the planned period for the implementation of the study |

78 |

70 |

54 |

66 |

It is difficult to unequivocally determine the adequacy of the project implementation costs |

78 |

72 |

62 |

68 |

Little (or no) criteria for reliable forecasting of the commercialization of an innovative product |

75 |

71 |

69 |

63 |

There is little possibility of a reliable assessment of the variability of market conditions for the period of commercialization of an innovative product |

80 |

77 |

68 |

64 |

There are seven branches of the economy, enterprises in which are most represented in scientific partnership with universities: the production of machinery and equipment, public health, and pharmaceuticals, information, and communication technologies, the production of electrical equipment, electronic and optical equipment, agriculture, the production of vehicles and equipment. Among other industries, the following is also represented in a sufficient degree in scientific partnership with universities: production of food products, metallurgical production, production and distribution of electricity, gas, and water; construction, chemical production.

A significant part of the scientific projects developed by universities in conjunction with regional enterprises belongs to such priority areas as information and telecommunication systems, life sciences, environmental management and energy efficiency, energy saving, nuclear energy. More than a third of projects are related to transport and space systems, and a quarter to the industry of Nano systems. Every fifth university also implements projects in the field of security and counter-terrorism.

On average, 90% of the regional enterprises of Russia participating in a joint scientific project with the universities are profitable, their profitability averages 40%; unprofitable make 10%. The average loss ratio is 30%. This is one of the factors that make it difficult to fully fund a joint project. There is another deterrent - a high degree of wear and tear on the equipment of enterprises. According to expert estimates, the age of the main process equipment used in the main production processes at the enterprise is on average 10.5 years. The degree of moral and physical wear and tear on the equipment of enterprises used in the main production processes is 30-35%. Among the surveyed heads of analytical (design) enterprise groups, 70% pointed to the enterprise's need to replace equipment in order to start the production of competitive products.

Before the formation of a corporate research team, at least 1-year passes and 1.5 years is required for the accumulation of financial resources and technical support for the study. The study itself lasts an average of 2 years. At least 1 year requires field testing of the final scientific product and 2 years is spent on the production implementation of the innovative product. As a result, the duration of the joint scientific project of universities and industrial enterprises takes an interval of 3 to 7 years, provided that the guaranteed state subsidy lasts no more than 3 years.

Own investments of universities and enterprises are reduced mainly to the values of the non-monetary form: technology, basic materials, intellectual property. If we take into account all types of capitalized investments in the research project, according to expert estimates, the share of the investment of the own funds of production companies in the joint research project with the universities is on average 70%; universities - 15%, the state budget - 15%. 90% of experts believe that on the whole, this is an effective ratio of investment support for corporate projects.

The transfer of scientific products to innovative production is provided mainly by two categories of specialists: engineers with analytical thinking and capable of transferring scientific products to production; managers specializing in the promotion of innovative products to the market. There is a deficit in both groups of specialists in production companies. In 2017, the average deficit of highly skilled engineers in the country's manufacturing companies averaged 35%, including a deficit of qualified specialists in innovative production - 25%, qualified managers to promote innovative products to the market - 30%.

Analysis of the output dynamics by universities of specialists in engineering specialties in 2011-2016 shows a wavy change in the output of engineers, depending on the variation in the total number of students of technical universities (Table 3).

Table 3

The output by Russian universities of specialists in engineering specialties in 2011-2016,

thousand people (Ministry of Education and Science of Russia, 2017)

Graduation in the engineering specialty |

Year of study |

|||||

2011 |

2012 |

2013 |

2014 |

2015 |

2016 |

|

Number of graduates in all engineering specialties |

134.1 |

126.6 |

116.5 |

108.1 |

136.1 |

96.4 |

Including: |

|

|

|

|

|

|

Development of mineral resources |

5.2 |

4.9 |

4.5 |

4.2 |

5.3 |

3.8 |

Energy sector and power engineering |

11.4 |

10.8 |

9.9 |

9.2 |

11.6 |

8.2 |

Metallurgy |

3.9 |

3.7 |

3.4 |

3.1 |

3.9 |

2.8 |

Machine building and metal working |

14.8 |

13.9 |

12.8 |

11.9 |

15.0 |

10.6 |

Aviation and rocket and space equipment |

5.0 |

4.7 |

4.3 |

4.0 |

5.0 |

3.6 |

Marine facilities |

1.5 |

1.4 |

1.3 |

1.2 |

1.5 |

1.1 |

Ground transport vehicles |

7.6 |

7.2 |

6.6 |

6.2 |

7.8 |

5.5 |

Technological machines and equipment |

12.6 |

11.9 |

11.0 |

10.2 |

12.8 |

9.1 |

Electrical technology |

6.4 |

6.1 |

5.6 |

5.2 |

6.5 |

4.6 |

Professional equipment |

5.2 |

4.9 |

4.5 |

4.2 |

5.3 |

3.8 |

Electronic engineering, radio engineering, and communication |

14.6 |

13.8 |

12.7 |

11.8 |

14.8 |

10.5 |

Automation and control |

12.3 |

11.6 |

10.7 |

9.9 |

12.5 |

8.9 |

Chemical engineering |

7.0 |

6.6 |

6.1 |

5.6 |

7.1 |

5.0 |

Food products technology |

6.3 |

6.0 |

5.5 |

5.1 |

6.4 |

4.5 |

Consumer goods technology |

4.2 |

3.9 |

3.6 |

3.4 |

4.2 |

3.0 |

Computer and Information Sciences |

16.1 |

15.2 |

14.0 |

12.9 |

16.4 |

11.4 |

Since 2013, universities have begun to pay more attention to the training of analytical engineers and technology transfer engineers. A similar trend develops with regard to the training of engineers-generalists. However, universities still focus on training engineers for two traditional profiles: engineers-professionals and engineers-technologists (Table 4).

Table 4

The share of technical universities preparing engineers of high qualification,%

Engineers |

Year of study |

|||

2011 |

2013 |

2015 |

2017 |

|

Engineer-professionals (carrying out creative work at all stages of creating an innovative product, its manufacture, and maintenance) |

61 |

69 |

75 |

78 |

Engineers-generalists (jack-of-all-trades) |

20 |

29 |

27 |

31 |

Engineers-technologists (ensuring the mastery of high technologies and their introduction into production) |

51 |

71 |

67 |

70 |

Engineers on technology transfer (providing the transfer of scientific ideas into technology, organizing on their basis the production of goods and services) |

16 |

22 |

25 |

28 |

To start production of competitive innovative products, according to 40% of the surveyed heads of analytical (design, project) teams of enterprises, it is necessary to introduce new motivational mechanisms for specialists, to carry out large-scale modernization of industrial areas, retraining and training of personnel, and introduce new management mechanisms at the enterprise.

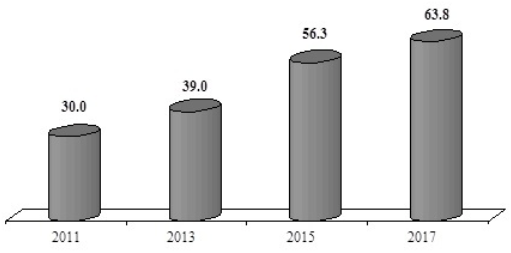

Regardless of the form of ownership of the executing organization, the scientific research carried out is mainly presented in three thematic areas: the development of new technologies for the production of preparations and materials; exploratory research: the development of concepts, methods, approaches to finding ways to solve practical problems; development, creation of new machines, installations, devices, systems. These three areas cover 85% of the total number of projects carried out within the federal state target program “Research and development in priority areas of development of Russia's scientific and technological complex for 2014-2020”. Another 5% accounted for the development of experimental and design work to create new, experimental samples of products. The cumulative indicator of the development stage of the products of the joint scientific project of universities and enterprises demonstrates that the execution of 60% of scientific projects are in a state no higher than the test, the approbation of the model, the product, and another 15% - no higher than the finalization of the model, the product after the test. As a result, the stage of transfer to production reaches no more than 15% of scientific production created by universities in conjunction with manufacturing enterprises (Figure 2).

Figure 2

The share of manufacturing companies that were in 2017 at various

stages of implementing the partnership scientific project, %

The share of products received within the framework of the scientific project carried out by universities together with enterprises and intended for transfer in the civil economy is as follows: healthcare, pharmaceuticals - 20%; general and nuclear energy - 9%; transport - 9%; electronics - 6%; cosmonautics - 5%; computer and information technologies - 5%; Oil and gas industry, including extraction - 4%; Exploration and production (excluding oil and gas) - 3.5%; Ecology - 3%; metallurgy and metalworking - 2.5%; agriculture - 2%; laser systems - 2%; machine building - 2%; communication - 1,5%; electrical engineering - 1%; the food industry - 1%; construction - 1%; communal services - 1%; water treatment - 1%; education - 1%; robotics - 1%; other areas of application or used in several areas - 18.5%.

The estimated average payback period for product development costs, if the final product of a research project implemented by a manufacturing enterprise jointly with the university, is introduced into production, is, according to experts, 3-4 years, which is generally not much. The time during which the produced scientific product, if it is introduced into production, can keep its relevance in the market of goods and services, according to experts, an average of 8 years.

The results of the expert assessment show that over the last 5 years, the desire of enterprises to fill the domestic market with innovative products of their own production was accompanied by an increase in demand in the regions for these products, moreover, in 2017 there was an acceleration in the growth rate of demand for products of enterprises engaged in innovative production (Fig. 3).

Figure 3 - The index of the profitability dynamics of enterprises in an effort to saturate regional markets with innovative products in 2013-2017 (the values of the index are variable in the following interval: “+1” - continuous growth in demand for products, “0” - demand has not changed, “-1” - continuous decline in demand for products)

Dependence on imports for raw materials or other components for products produced by enterprises is quite significant - 25%. This dependence is especially high in such sectors as textile and clothing production (40-45%), production of coke and petroleum products (40%), healthcare and pharmaceuticals (30-35%), leather, leather products and footwear (30%), information and communication technologies (30%), production of vehicles and equipment (25%). The least dependence of enterprises on the import of raw materials, machinery, and technology in such industries as the production and distribution of electricity, gas, and water, food production, chemical production, and the production of rubber and plastic products.

The final product of the joint scientific project is introduced only by the manufacturing enterprise in 50% of cases, in 40% of cases - by the production enterprise together with the university. Enterprises seek to introduce products obtained as a result of a partnership implementation of a scientific project independently only in the following sectors: production of leather, leather and footwear products, production of coke and petroleum products, information and communication technologies, wood processing and wood products, machinery and equipment manufacturing, production of vehicles and equipment, production of electrical equipment, electronic and optical equipment, textile and clothing production , transport, chemical production.

As experts pointed out, the main factors hampering the effective implementation of the corporate scientific project carried out by manufacturing enterprises in conjunction with universities are a lack of finance, skilled specialists in innovative production, bureaucratic hindrances when launching the production of an innovative product; a shortage of qualified managers to promote innovative products to the market, bureaucratic hindrances when promoting an innovative product to the market.

These data allow for making a number of prognostic conclusions about the future development of innovative production.

1. The state policy of subsidizing the interaction of science and production creates a serious problem of the functioning of regional enterprises - inertial attachment to the internal market. Therefore: 65% of enterprises in their functioning and product development are guided by orders from other enterprises, organizations, and 45% - on the favorable development of the national market situation; another 20% - on subsidies from the state or state orders, the gain due to the difference in the exchange rate. Those focusing on the effective demand of the population - 25%, the growth in the volume of orders from foreign consumers - 20%. The above-mentioned indicators are typical for enterprises in all sectors of the Russian economy.

2. The fact that only in 55% of cases a risk assessment was carried out before the conclusion of a contract on joint research work of universities and enterprises indicates that the market demand for the scientific product being developed is insufficiently studied. Only 40% of the enterprises surveyed made an assessment of the degree of assuring assistance to the product obtained as a result of scientific research to strengthen their position in the market of goods and services, 30% estimated the maximum duration in time of profitable use of the scientific product by the enterprise.

3. Among the surveyed experts, 75% indicated that the enterprise has little opportunity to reliably estimate the variability of market conditions during the commercialization of the innovative product, while 60% said that the enterprise has little (or no) criteria for reliable forecasting of the commercialization guarantee of the innovative product.

4. Production organizations are interested in the finished product, and not in its theoretical concept. The research results showed that universities as a whole are focused on the introduction of the produced scientific product primarily in the regional market.

5. Many departments and scientific divisions of universities are in a difficult situation, if desired, to introduce a scientific product into production: 25% of specialized technical departments and research organizations of universities participating in a joint scientific project with territorial enterprises do not have the experience of promoting intellectual products to the market, 15% do not have managers to promote scientific products to the market, 20% of experts indicated lack of demand from the side production organizations on the scientific products being created.

6. The fact that in 85% of cases the initiator of a scientific topic for joint development with a manufacturing enterprise is the university, creates a large number of risks of personnel, financial and transfer of scientific products.

7. The expert survey results indicate that the majority of enterprises do not have a single standard project documentation, which includes both organizational and substantive issues of joint implementation of a scientific project. Separate blocks of coordination of work on the project are presented in fragmentary. Most often there is a description of the main areas of scientific cooperation between the enterprise and the university, less often - the mechanisms for joint examination of new scientific products and the formation of a system for managing intellectual property.

8. Capital intensity, if this means financial means, works on the implementation of a joint scientific program by the university and the enterprise is reduced to no more than to the amount indicated in the partnership agreement. Own investments of the university and the enterprise are reduced basically to the values of the non-monetary form: technology, basic materials, intellectual property. Subsequently, this makes it difficult to assess the profitability of the transfer of a scientific product and its production. However, in the opinion of 90% of experts, the joint scientific project on the final product is generally effective. This means that in the overall structure of investments in a joint scientific project there is no need to increase the share of the state budget (now it averages 15-20%).

9. A unified standardized document for the coordination of the entire stage of partnership between enterprises and universities in the implementation of a scientific project can be a joint business plan, which today has only every second enterprise participating in a scientific project with the university. In most cases, the functional structure of current business plans is not completely complete.

10. The results of the expert assessment indicate that over the past 5 years, the dynamics of demand for enterprise products in the territories is positive. Moreover, in 2017 there was a significant acceleration in the growth rate of demand for enterprise products. At the same time, the dependence on imports of raw materials or other components for products produced by enterprises is significant - 25%. In new technologies, up to 90% of the enterprises surveyed need to develop production. The source of the transfer of new technologies to the enterprise, according to 70% of experts, is available in the Russian Federation, moreover, according to 35% of experts, there is in the region where the enterprise is located. According to experts, the main problems that impede the transition of the enterprise to the production of innovative products are the inadequacy of state support and funding for the provision of resources for research, design and engineering work, the shortage of specialists focused on the creation of innovative products, the growth in production gap in the range of products from similar industries abroad.

11. Despite the fact that 60-75% of experts pointed out the difficulties of reliable assessment of the variability of the market conditions and the guarantee of commercialization of the innovative product, 90% of experts believe that the lack of knowledge of the state of the regional or federal innovation product market does not interfere with the effective implementation of the scientific project. This indicates a serious underestimation of reliable information about the market. Successful implementation of a scientific project in terms of final scientific products is not yet a guarantee of the capacity to realize the final product.

12. The main problem of the functioning of territorial enterprises is the inertial attachment to the regional (domestic) market and the lack of a goal to enter the international market. Such a goal does not contribute to strengthening the competitiveness of enterprise products.

13. On average, 90% of enterprises participating in a scientific project jointly with universities are profitable. Loss of 10% of enterprises makes it difficult for them to fully fund their scientific project with a university.

14. According to the estimations made by the managers and specialists of the enterprises, due to the increased demand for products, budgetary state support of joint scientific projects in the following 15 sectors of the economy is expedient: manufacture of machinery and equipment; health and pharmaceuticals; information and communication technologies; production of electrical equipment, electronic and optical equipment; agriculture; manufacture of vehicles and equipment; mining; metallurgical production; production of food products; production and distribution of electricity, gas and water; building; transport; communication.

15. The structure of spending by specialized technical departments of universities of funds allocated for the study cannot be called effective. Various “organizational” deductions from the funds invested in a joint project are on average 33%; the payroll fund for researchers - 40% of the total investment in the project. The remaining 27% is the cost of technical support for the joint project.

16. Almost all groups of experts indicated that, depending on the degree of initial development of the problem, the duration of the implementation of the scientific project takes an interval of 3-7 years. From this, it follows that the minimum planned period for the university to carry out a joint scientific project with the production enterprise must be at least 3 years, otherwise there is a danger that the final scientific product will not be brought to the stage of transfer and production of innovative products.

17. The organization of effective joint scientific program implementation is still difficult due to the lack of a sustainable risk assessment of the functional stages of the project implementation. The greatest difficulty is in the marketing component of the project and if it is expressed in the fact that there are few (or not) criteria for forecasting the guarantee of commercialization of an innovative product, as well as the possibility of a reliable assessment of the variability of market conditions during the commercialization of an innovative product.

18. Statistical accounting of the output of engineers and managers is poor, the level of reliability of information is low and there is no detailed segmentation by specialization. This complicates regulating the training of specialists for innovative production in accordance with the requests of enterprises. As a result, at least a third of graduates of engineering faculties after an employment pass qualification improvement, or change the profile of engineering specialization. Because of the lack of a clear specialization and relevant production practices, managers do not adequately represent the nature of their future work, and in general, recruitment to management faculties without considering real demand from enterprises leads to overproduction of management specialists by universities. From what has been said, it is necessary to correct the training of engineers and management specialists in accordance with the requests of production enterprises.

This research was supported by the Russian Science Foundation (grant № 16-18-10420 “Continuing education and science intensive productions: institutes and practices of interaction”) and conducted in the Institute of Sociology of FCTAS RAS.

AVIMANYU, Datta, REED, Richard, JESSUP, Len. Commercialization of Innovations: overarching framework and research agenda. American Journal Of Business. Vol 28, year 2013, issue 2, page 147-191.

BAJADA, C., TRAYLER, R. Interdisciplinary Business Education: Curriculum through Collaboration. Education & Training. Vol 55, year 2013, issue 4-5, page 385-402.

BILGE, A.K., TANYEL, O.E. Redefining space in production networks: network centrality and R&D activities in Ankara defense and aviation cluster. Gazi University Journal of Science. Vol 2, year 2017, issue 30, page 17-33.

BUNYAK, N.M. Entrepreneurial University: the essence and features of the formation. Juvenis scientia. Vol 2, year 2016.

CASPER, S. (2007). Creating Silicon Valley in Europe. Public Policies towards New Technology Industries. Oxford: Oxford University Press.

CASTILLO, V., MAFFIOLI, A., STUCCHI, R., ROJO, B. Knowledge Spillovers of Innovation Policy through Labor Mobility: An Impact Evaluation of the FONTAR Program in Argentina. Inter-American Development Bank Working paper series. Year 2014, issue IDB-WP-488, page 1-30.

Center of Social Forecasting and Marketing (2017). The number of students, teaching and teaching staff, the potential number of educational organizations at all levels of education: the forecast until 2035. Мoscow.

ETZKOWITZ, H. (2018). Universities and Commercialization of Knowledge. New Dimensions for the 21 Century. Cambridge: Cambridge University Press.

GEOGHEGAN,-Quinn. (2012). From Innovation Emergency to Economic Growth. Innovation Lecture. The Hague.

GORSHKOV, M.K., KLYUCHAREV, G.A. (2011). Continuous education in the context of modernization. Moscow: Center of Social Forecasting and Marketing.

GORSHKOV, M.K., SHEREGI, F.E. The scientific potential of universities in the real sector of the economy. Presidential control. Newsletter. Year 2011, issue 4.

The Government of the Russian Federation. (2010). Decree No. 218 “On Measures of State Support for the Development of Cooperation between Russian Higher Educational Institutions and Organizations Implementing Comprehensive Projects for the Creation of High-Tech Production”.

HEIFETS, B., SELEKHOV, J. China: innovative development in crisis conditions. Problems of the Far East. Year 2010, issue 1, page 46-56.

IASP. (2018). International Association of Science Parks. Retrieved from: http://www.iaspworld.org/

KANEVA, M., UNTURA, G.A. The Knowledge Economy in China and Public-Private Partnerships of Universities. European Journal of Economics and Management. Vol 1, year 2014, issue 1, page 193-211.

KANG, B-J. Exploring Governance Models of Science & Research Parks and Related Organizations. World Technopolis Review. Vol 1, year 2014, issue 3, page 39-54.

KLYUCHAREV, G.A., POPOV, M.S. State policy in the sphere of interaction between science and business. Education and science in Russia: the state and development potential. Collection of scientific papers. Year 2017, issue 2, page 434-337.

KLYUCHAREV, G.A., POPOV, M.S., CHURSINA, A.V. Small Science Enterprises – the experience of the first ten years. Education and science in Russia: state and development potential. Collection of scientific papers. Year 2017, issue 2, page 357-381.

KLYUCHAREV, G.A., POPOV, M.S., SAVINKOV, V.I. (2017). Education, science, and business: new facets of interaction. Moscow: Institute of Sociology of the Russian Academy of Sciences.

KOTELNIKOV, N.V., NAGAEVA A.V. Analysis and development of the Technopark as an object of innovative infrastructure. Bulletin of Tomsk Polytechnic University. Vol 324, 2014, issue 6, page 126-133.

LINK, A.N., YEONG YANG, U. On the growth of Korean technoparks. International Entrepreneurship and Management Journal. Year 2017, issue 1-6.

The Ministry of Education and Science of Russia. (2017). Education in Russia: 2017. Statistical collection. Moscow: Moscow Technological University.

OLCAY, G.A., BULU, M. Technoparks and Technology Transfer. Offices as Drivers of an Innovation Economy: Lessons from Istanbul's Innovation Spaces. Journal of Urban Technology. Vol 23, year 2016, issue 1, page 71-93.

OSIPOV, G.V., SHEREGI, F.E. (2017). Sociology of science and education. Integration of university science and production. Moscow: Yurayt.

PARK, J.H. Brokerage activities in regional innovation networks: the case of Daegu Technopark in Korea. International Journal of Urban Sciences. Vol 2, year 2016, issue 20, page 260-284.

The President of the Russian Federation. (2011). Decree No. 899 “On the approval of priority directions for the development of science, technology and technology in the Russian Federation and the list of critical technologies of the Russian Federation”.

Proprof.ru. (2018). New May decrees of the President of 2018. Retrieved from: http://proprof.ru/stati/careera/pro-zarplatu/mayskie-ukazy-2018

REHMAN, N. A Complementary Relationship between Networks and Organizational Innovation Activities: Evidence from Chile. Journal of Innovation Economics & Management. Vol 2, year 2017, page 83-106.

SAVINKOV, V.I., BAKLANOV. P.A. (2016). The role of science in the development of innovative production: expert evaluation. Moscow: Center of Social Forecasting and Marketing.

Socioprognoz.ru. (2018). The results of studies in an open form. Retrieved from: www.socioprognoz.ru

VASQUEZ-URRIAGO, A.R., BARGE-GIL, A., RICO, A.M. Science and Technology Parks and cooperation for innovation: Empirical evidence from Spain. Research Policy. Vol 1, year 2016, issue 45, page 137-147.

YANIKTEPE, B., FEDAI, M., AKSOY, A. Technoparks as an Actor of Regional Development: An Evaluation on Turkey. Journal of Applied Economic Sciences. Vol 1, year 2016, issue 39, page 155-157.

ŽIŽKA, M., VALENTOVÁ, V.H., PELLONEOVÁ, N., Štichhauerová, E. The Effect of Clusters on the Innovation Performance of Enterprises: Traditional vs New Industries. Entrepreneurship and Sustainability Issues. Vol 5, year 2018, issue 4, page 780-794.

1. Candidate of Sciences (Philosophy), Leading Researcher, Institute for Socio-Political Research of the Russian Academy of Sciences, 119333, Moscow, Russia, 6 Fotiyeva Str., building 1. State Center "Interphysica". E-mail: f-sheregi45@inbox.ru

2. Doctor of Sciences (Sociology), Professor, Russian State Social University, 107076, Moscow, Russia, 4 Wilhelm Peak Str. E-mail: visavinkov2007@senat.gov.ru

3. Candidate of Sciences (Economics), Associate Professor of the Russian State Social University, 107076, Moscow, Russia, 4 Wilhelm Peak. E-mail: Baklanov_pa97@aprf.gov.ru